Why is Handmade Furniture so Expensive?

Have you ever wondered why handmade furniture is so expensive? You may have seen some beautiful pieces of custom solid wood tables or chairs in a custom furniture store or online, and felt tempted to buy them. But then you saw the price tag and changed your mind. Why do these pieces cost so much more than the mass-produced furniture you can find in any store?

The answer is not simple, but it involves many factors that affect the quality, durability, customization, personalization, artistry, and uniqueness of handmade furniture. In this article, we will explain these factors in detail, and show you why handmade furniture is worth investing in. We will also compare handmade furniture with mass-produced furniture, and show you how the latter is often inferior in terms of materials, craftsmanship, and design.

Key Takeaways

| Factor | Handmade Furniture | Mass-Produced Furniture |

|---|---|---|

| Quality | High-quality materials and craftsmanship | Cheap materials and low-quality finishes |

| Durability | Long-lasting and sturdy | Short-lived and fragile |

| Customization | High degree of customization and personalization | Limited options and standard sizes |

| Artistry | Creative and skillful design | Lacks originality and character |

| Uniqueness | Each piece is unique and beautiful | Each piece is identical and artificial |

Quality and Durability

One of the main reasons why handmade furniture is so expensive is because it offers higher quality and durability than mass-produced furniture. Quality and durability depend on the materials and craftsmanship that go into making a piece of furniture.

Handmade furniture is made with high-quality materials that are carefully selected for their strength, beauty, and suitability. Some of the most common types of wood used in handmade furniture are:

- Walnut: rich brown color with dark streaks, fine texture, high density, good resistance to shock

- Ash: light brown color with straight grain patterns, coarse texture, medium density, good bending strength

- White Oak: light tan color with wavy grain patterns, medium texture, high density, high resistance to rot

Handcrafted furniture is also made with high-quality finishes that protect the wood from moisture, stains, scratches, and UV rays. Some of the most common types of finishes used in handmade furniture are:

| Finish Type | Advantages | Disadvantages |

|---|---|---|

| Oil-based | Easy to apply, enhance the natural color and grain of the wood, provide a warm and natural look | Yellows the wood |

| Water-based | Durable, resistant to liquids, provide a clear and non-yellowing look | May raise the grain or alter the color of the wood |

| Wax | Simple to use, provide a soft and smooth feel | Offer little protection against moisture or abrasion |

| Natural | Eco-friendly, provide a rich and deep look | May be difficult to apply or repair |

Another aspect of quality and durability is the hardware that adds functionality and style to the piece. Some of the most common types of hardware used in handmade furniture are:

- Hinges: allow the doors or lids to open and close

- Knobs: allow the drawers or cabinets to be pulled or pushed

- Pulls: allow the drawers or cabinets to be pulled or pushed

- Locks: allow the doors or drawers to be secured or unlocked

- Slides: allow the drawers to slide in and out smoothly

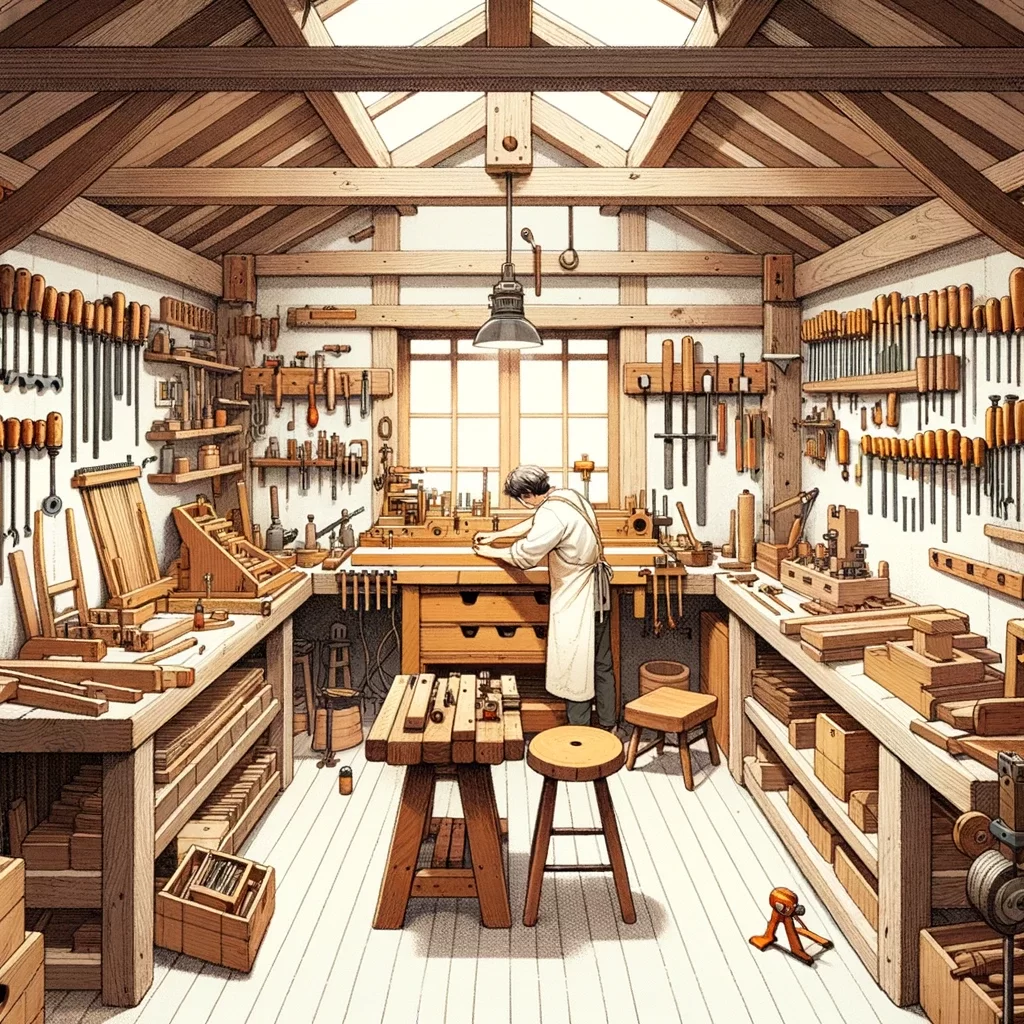

The last but not least factor that contributes to quality and durability is the craftsmanship that ensures its durability and longevity. Craftsmanship is the skill and art of making something by hand, using tools and techniques that have been passed down from generation to generation. Some of the most common skills and techniques used in handmade furniture are:

- Joinery: the way of joining two pieces of wood together, such as dovetail joints or mortise and tenon joints

- Carving: the way of creating shapes or patterns on the surface of wood, such as relief carving or chip carving

- Turning: the way of shaping wood on a lathe, such as spindle turning or bowl turning

- Inlaying: the way of inserting pieces of different materials into wood, such as marquetry or parquetry

In contrast, mass-produced furniture is often made with cheap materials and low-quality finishes that compromise its quality and durability. Mass-produced furniture is usually made with veneers or laminates that cover up the natural wood underneath, making each piece look uniform and artificial. Mass-produced furniture is also made with low-quality hardware that adds little functionality or style to the piece. Mass-produced furniture is also made with low-quality craftsmanship that compromises its durability and longevity.

Customization and Personalization

Another reason why handmade furniture is so expensive is because it offers a high degree of customization and personalization, which allows customers to get exactly what they want and need. Customization and personalization are the ability to modify or tailor a piece of furniture according to the customer’s preferences and requirements.

Handcrafted furniture offers a wide range of options for customers to choose from, such as size, shape, color, style, design, and features. These options allow customers to create a unique and functional piece of furniture that fits their space, matches their decor, suits their taste, and meets their needs.

One of the benefits of customization and personalization is that customers can have a piece of furniture that reflects their personality and style. No two pieces of handmade furniture are exactly alike, as each piece is made with different materials, finishes, hardware, and craftsmanship. Each piece also has its own story and history, as it is made by a specific person or a small team of people who put their passion and skill into it. Customers can also add their own touch to their furniture, such as engraving their name or initials, adding a logo or a symbol, or choosing a special theme or motif.

Another benefit of customization and personalization is that customers can have a piece of furniture that serves their purpose and solves their problems. Customers can specify the features and details that they want or need in their furniture, such as drawers, shelves, cabinets, extensions, or hidden compartments. These features and details can help customers organize their items, store their belongings, expand their space, or hide their secrets.

If you’re located in Alberta or BC, Taitlin Studio offers a variety of customizable furniture options in your area. Check out our pages for more information on furniture options in these regions:

Alberta:

- Edmonton, Sherwood Park & St. Albert Furniture

- Calgary Furniture

- Lethbridge Furniture

- Grande Prairie Furniture

- Red Deer Furniture

- Medicine Hat Furniture

British Columbia Furniture

Each of these locations provides the same high-quality craftsmanship and a wide range of customization options to meet your needs. Whether you’re looking for custom-made dining tables, coffee tables, or other handcrafted pieces, we’re here to help you create the perfect furniture for your home or office.

Taitlin Studio is a custom handcrafted furniture company that provides a broad range of customization options for their dining tables. Customers can choose from different wood types, such as Walnut, Ash, White Oak, Cherry, Maple, and reclaimed timbers. These wood types have different characteristics that affect their appearance, hardness, stability, and resistance to decay. Customers can also choose from different stain colors, such as natural, walnut, espresso, black, or custom. These stain colors have different effects on the wood color and grain. Customers can also choose from different leg styles, such as X-legs, U-legs, A-legs, or custom. These leg styles have different shapes and materials that affect the table stability and style. Customers can also choose from different edge profiles, such as square, roundover, chamfer, or live edge. These edge profiles have different angles and curves that affect the table edge shape and look.

Here is an example of how a customer can customize their dining table at Taitlin Studio:

| Option | Choice |

|---|---|

| Wood Type | Walnut |

| Stain Color | Espresso |

| Leg Style | U-legs |

| Edge Profile | Live edge |

The result is a stunning custom solid wood table that has a rich brown color with dark streaks, a fine texture, a high density, and a good resistance to shock. The table also has a modern and sleek look with its U-shaped metal legs and a rustic and natural look with its live edge that follows the natural shape of the wood.

In contrast, mass-produced furniture offers limited options and standard sizes for customers to choose from. Factory-produced furniture is usually made with veneers or laminates that cover up the natural wood underneath, making each piece look uniform and artificial. Mass-produced furniture is also made with low-quality hardware that adds little functionality or style to the piece. Factory-produced furniture is also made with low-quality craftsmanship that compromises its durability and longevity.

Mass-produced furniture offers limited options for customers to choose from, such as color, brand, or features. These options do not allow customers to create a unique and functional piece of furniture that fits their space, matches their decor, suits their taste, or meets their needs.

One of the drawbacks of limited options is that customers may end up with a generic piece of furniture that lacks personality and style. Many pieces of mass-produced furniture are identical and artificial, as they are made with the same materials, finishes, hardware, and craftsmanship. Many pieces also have no story or history, as they are made by robots or machines that produce large quantities of identical pieces that lack individuality and charm. Customers may also have no way to add their own touch to their furniture, as they may not be able to engrave their name or initials, add a logo or a symbol, or choose a special theme or motif.

Another drawback of limited options is that customers may end up with an impractical piece of furniture that does not serve their purpose or solve their problems. Customers may not be able to specify the features and details that they want or need in their furniture, such as drawers, shelves, cabinets, extensions, or hidden compartments. These features and details can help customers organize their items, store their belongings, expand their space, or hide their secrets.

Artistry and Uniqueness

Another reason why handmade furniture is so expensive is because it is a form of art that reflects the creativity and skill of the maker, as well as the personality and taste of the customer. Artistry and uniqueness are the qualities that make a piece of furniture stand out from the rest, and express a sense of beauty and meaning.

Bespoke furniture is a form of art that reflects the creativity and skill of the maker, who uses their imagination and talent to create something original and beautiful. The maker uses various tools and techniques to shape, carve, turn, or inlay the wood, creating stunning details, patterns, textures, curves, or carvings. The maker also uses their knowledge and experience to select the best materials, finishes, hardware, and craftsmanship for each piece, ensuring its quality and durability. The maker also puts their passion and emotion into each piece, giving it a soul and a story.

Handcrafted furniture is also a form of art that reflects the personality and taste of the customer, who has the freedom and flexibility to customize and personalize their furniture according to their preferences and requirements. The customer can choose from a wide range of options for their furniture, such as size, shape, color, style, design, and features. The customer can also add their own touch to their furniture, such as engraving their name or initials, adding a logo or a symbol, or choosing a special theme or motif. The customer can also have a unique piece of furniture that suits their space, matches their decor, meets their needs, and expresses their style.

One of the benefits of artistry and uniqueness is that handmade furniture can enhance the aesthetic appeal and value of any space. Handmade furniture can add charm and character to any room, creating a warm and inviting atmosphere. Bespoke furniture can also attract attention and admiration from anyone who sees it, making a lasting impression. Handmade furniture can also increase in value over time, as it becomes more rare and desirable.

Another benefit of artistry and uniqueness is that handmade furniture can provide satisfaction and joy to both the maker and the customer. Local handcrafted furniture can be a source of pride and accomplishment for the maker, who can showcase their skills and creativity. Handwrought furniture can also be a source of pleasure and happiness for the customer, who can enjoy owning and using something that is made just for them.

Cost-Effectiveness

Crafted furniture is more cost-effective than mass-produced furniture in the long run, as it lasts longer and retains its value. They are made with high-quality materials and craftsmanship that ensure its durability and longevity. Custom-made furniture is also made with solid wood that has natural variations in grain, color, and texture, making each piece unique and beautiful. Handmade furniture is also made with high-quality finishes that protect the wood from moisture, stains, scratches, and UV rays.

The average lifespan of a handmade piece of furniture can vary depending on the type of wood, the quality of craftsmanship, and the level of maintenance. However, some estimates suggest that a well-made piece of bespoke furniture can last for 50 years or more. On the other hand, the average lifespan of a mass-produced piece of furniture can range from 2 to 10 years, depending on the quality of materials and construction. Factory produced furniture is more likely to break down, wear out, or go out of style faster than handmade furniture.

To compare the cost-effectiveness of handmade furniture and mass-produced furniture, we can use a simple formula:

Cost-Effectiveness = (Lifespan x Value) / Cost

Lifespan is the number of years that a piece of furniture can be used before it needs to be replaced. Value is the amount of money that a piece of furniture can be sold for or appraised at. Cost is the amount of money that a piece of furniture is bought for.

Using this formula, we can calculate the cost-effectiveness of a handmade dining table and a mass-produced dining table. A handmade dining table can cost anywhere from $2,000 to $10,000 or more, depending on the size, design, and materials. A mass-produced dining table can cost anywhere from $200 to $2,000 or more, depending on the quality, brand, and features. For simplicity, we will assume that a handmade dining table costs $5,000 and lasts for 50 years, and that a mass-produced dining table costs $1,000 and lasts for 5 years. We will also assume that both tables have the same value as their cost when they are bought.

Using these assumptions, we can calculate the cost-effectiveness of each table as follows:

Cost-Effectiveness of Handmade Dining Table = (50 x 5000) / 5000 = 50 Cost-Effectiveness of Mass-Produced Dining Table = (5 x 1000) / 1000 = 5

As we can see, the cost-effectiveness of the handmade dining table is much higher than the cost-effectiveness of the mass-produced dining table. This means that the handmade dining table performs its function better relative to its cost than the mass-produced dining table.

Of course, these calculations are based on hypothetical numbers and may not reflect the actual prices and lifespans of different types of tables. However, they illustrate the general principle that handmade furniture is more cost-effective than mass-produced furniture in the long run.